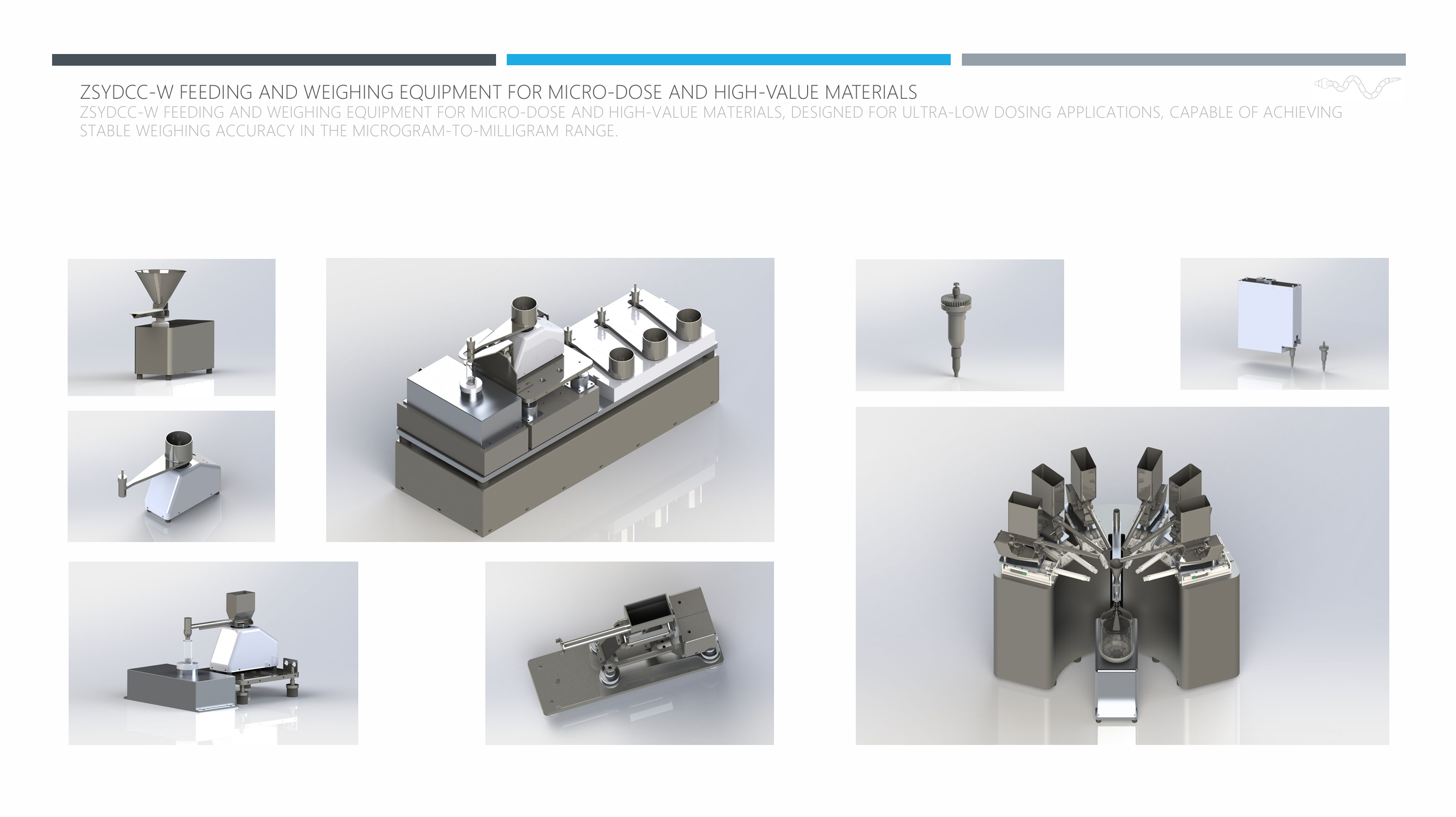

Technological Breakthrough

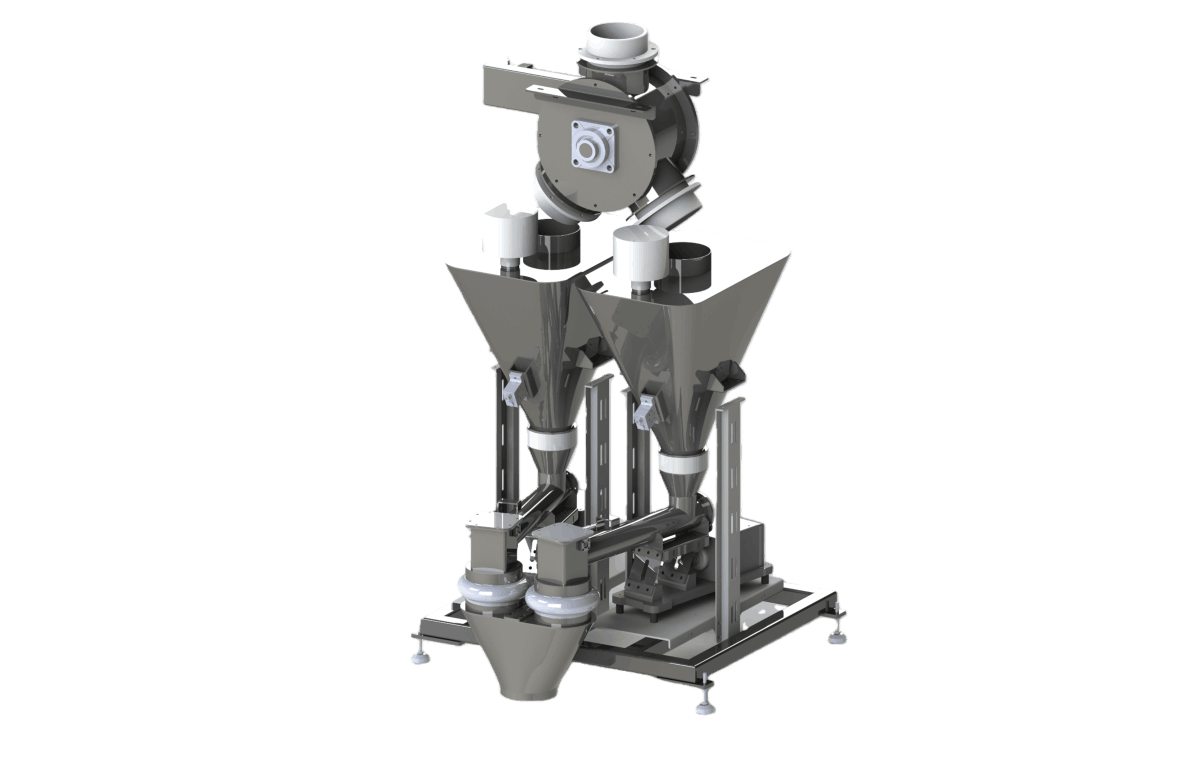

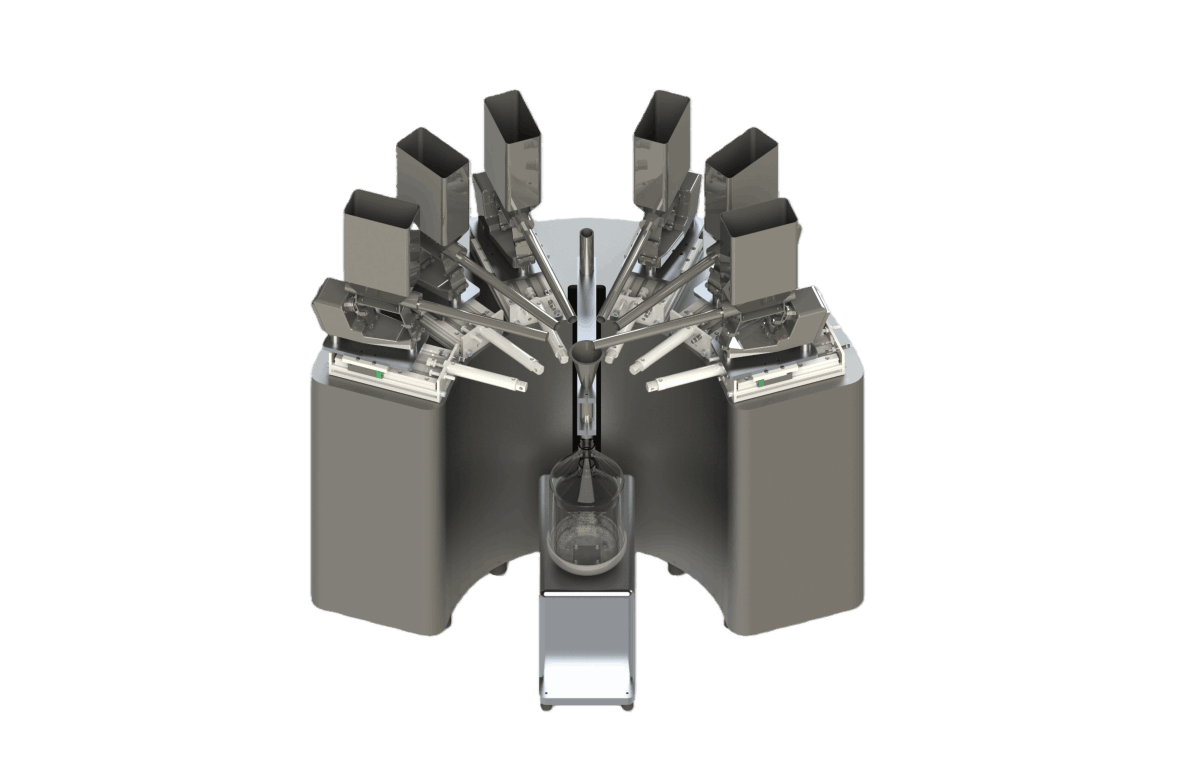

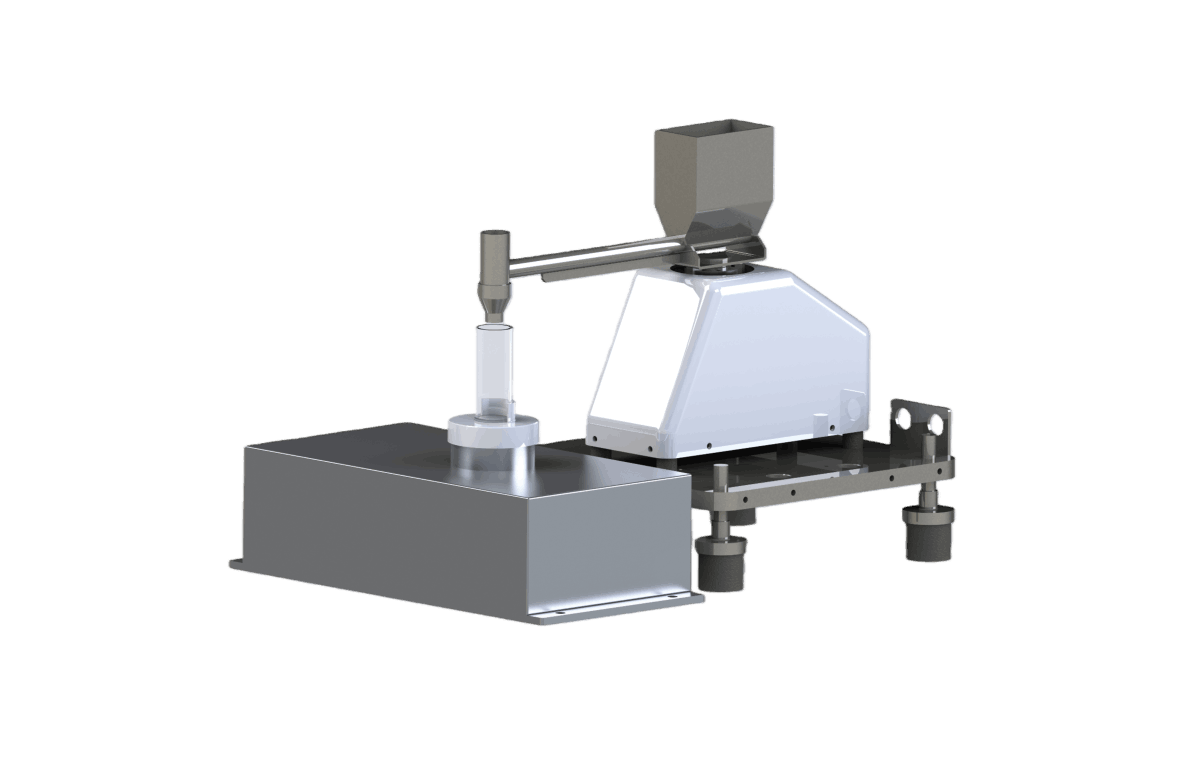

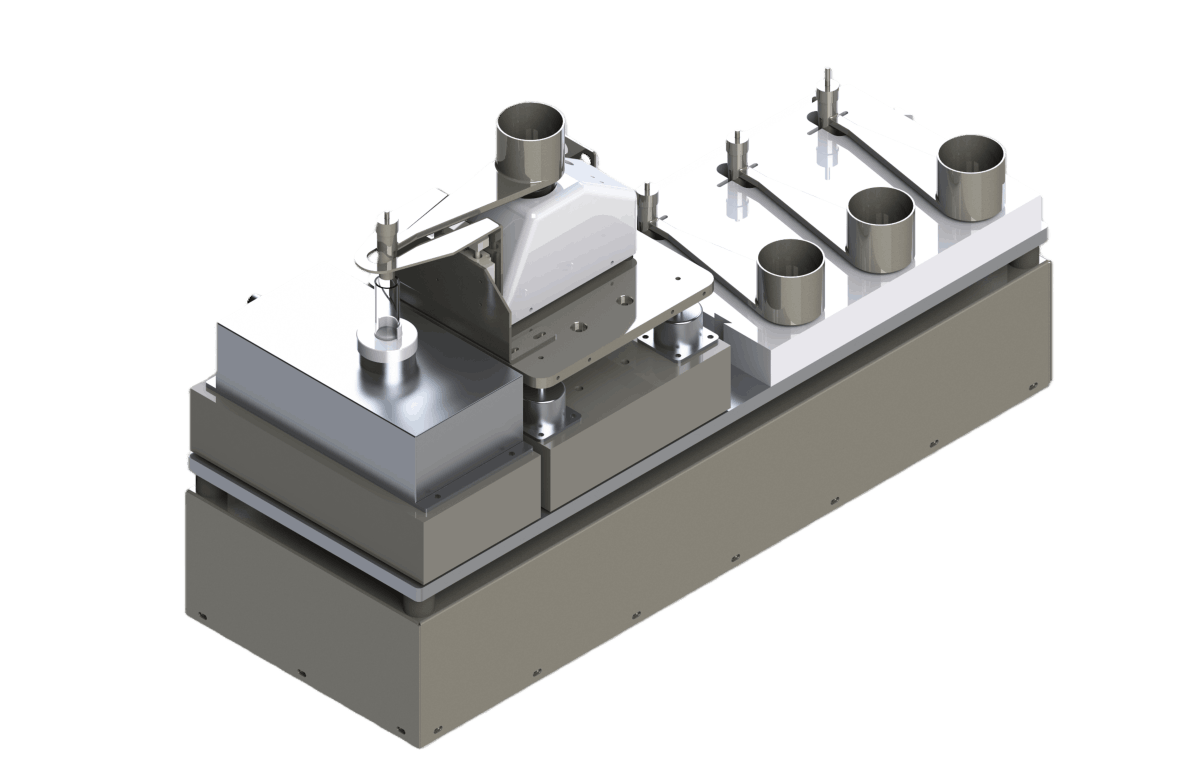

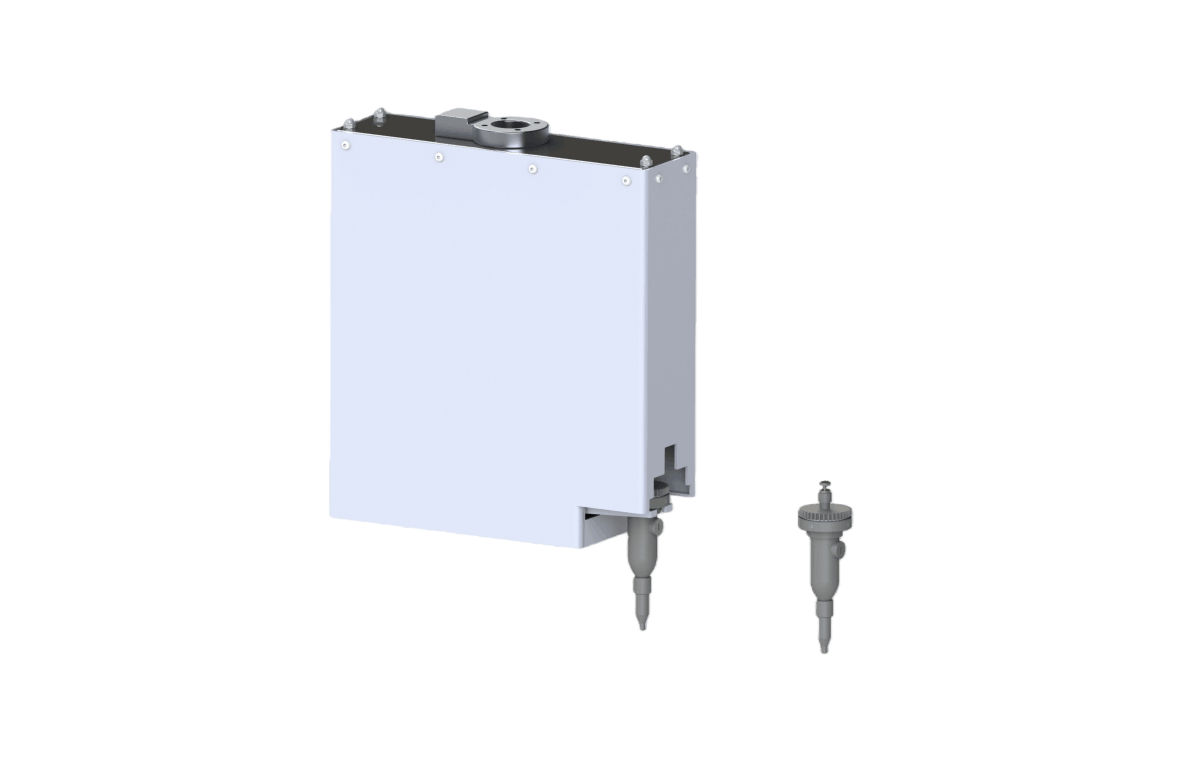

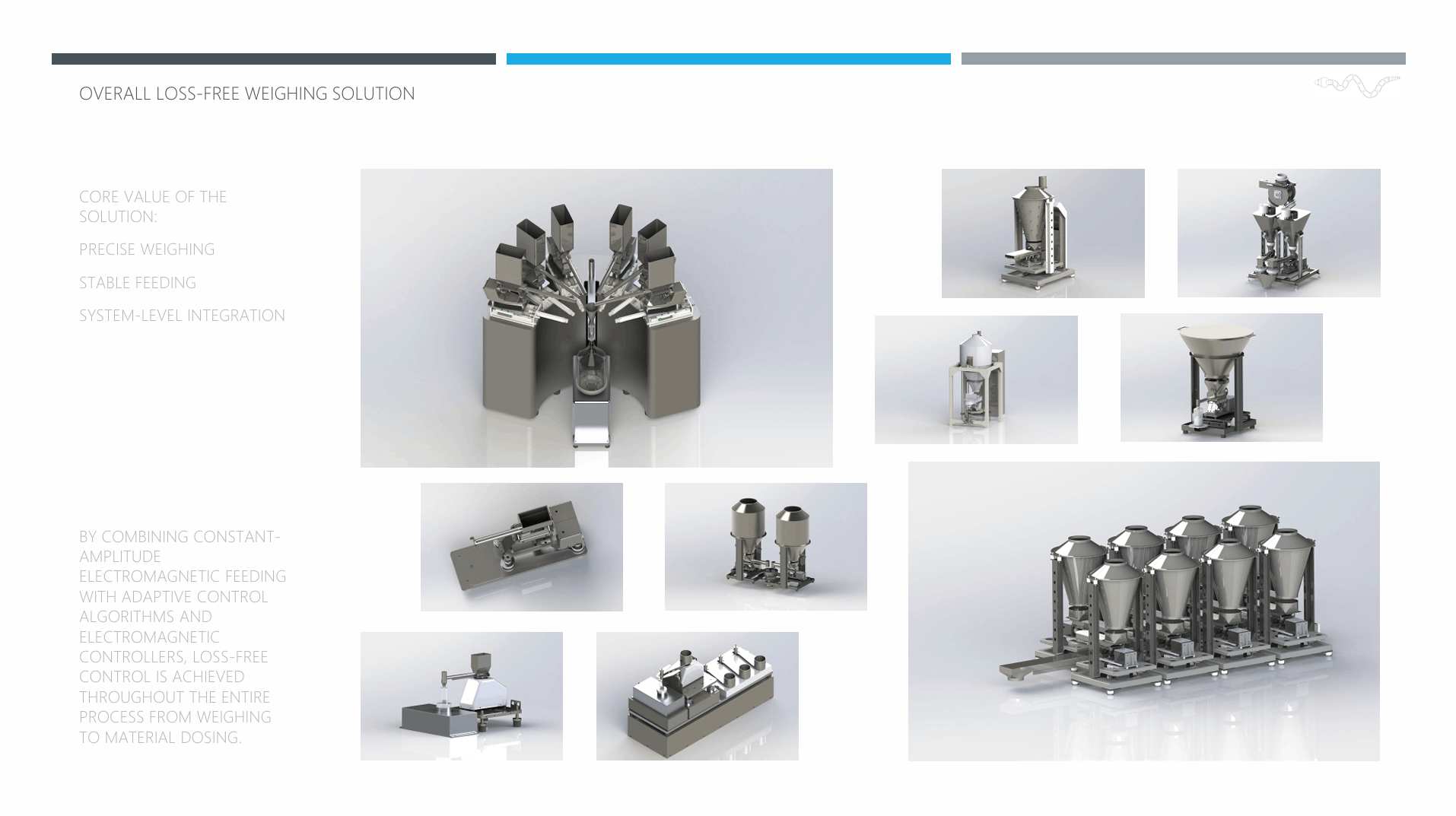

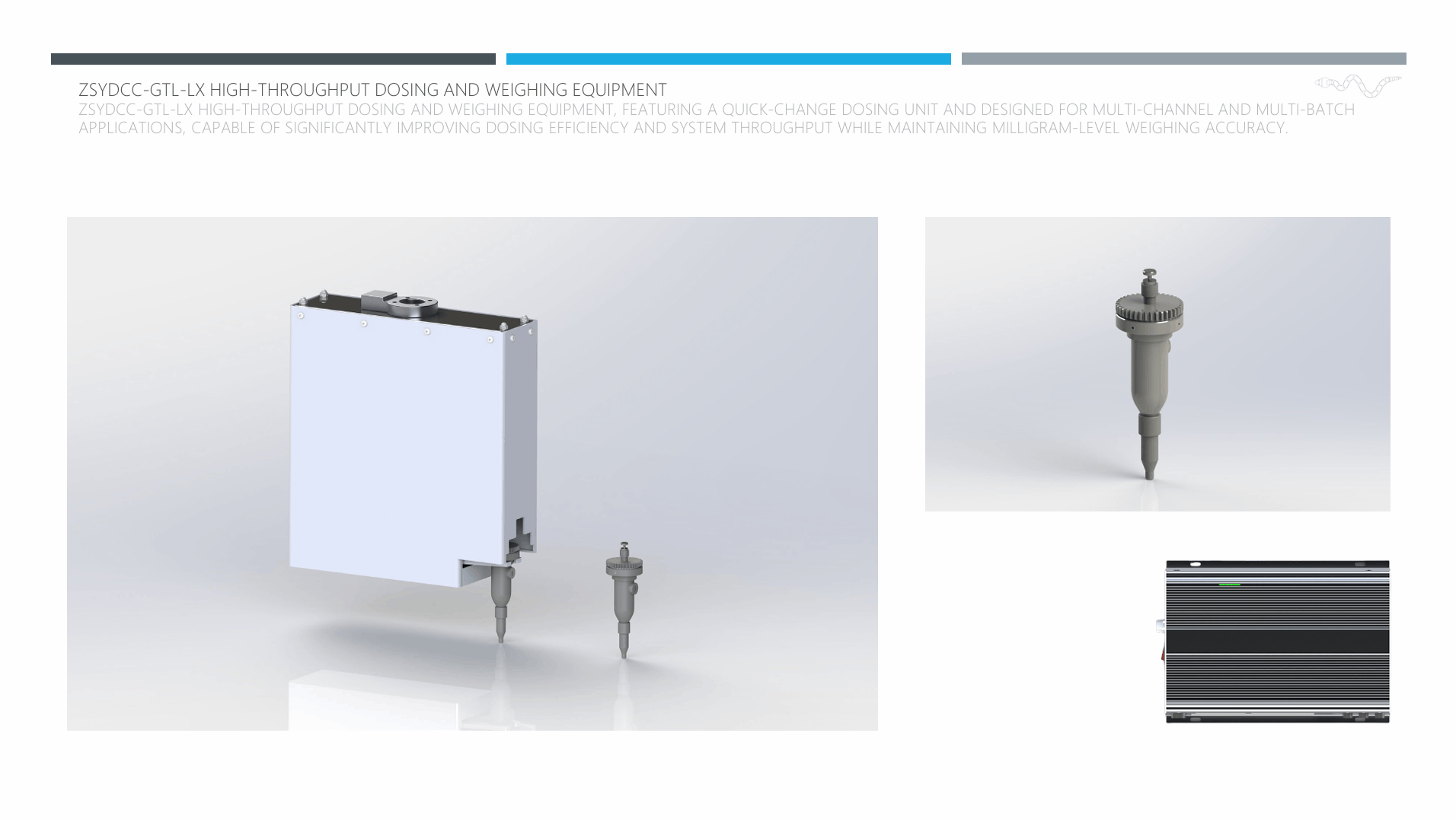

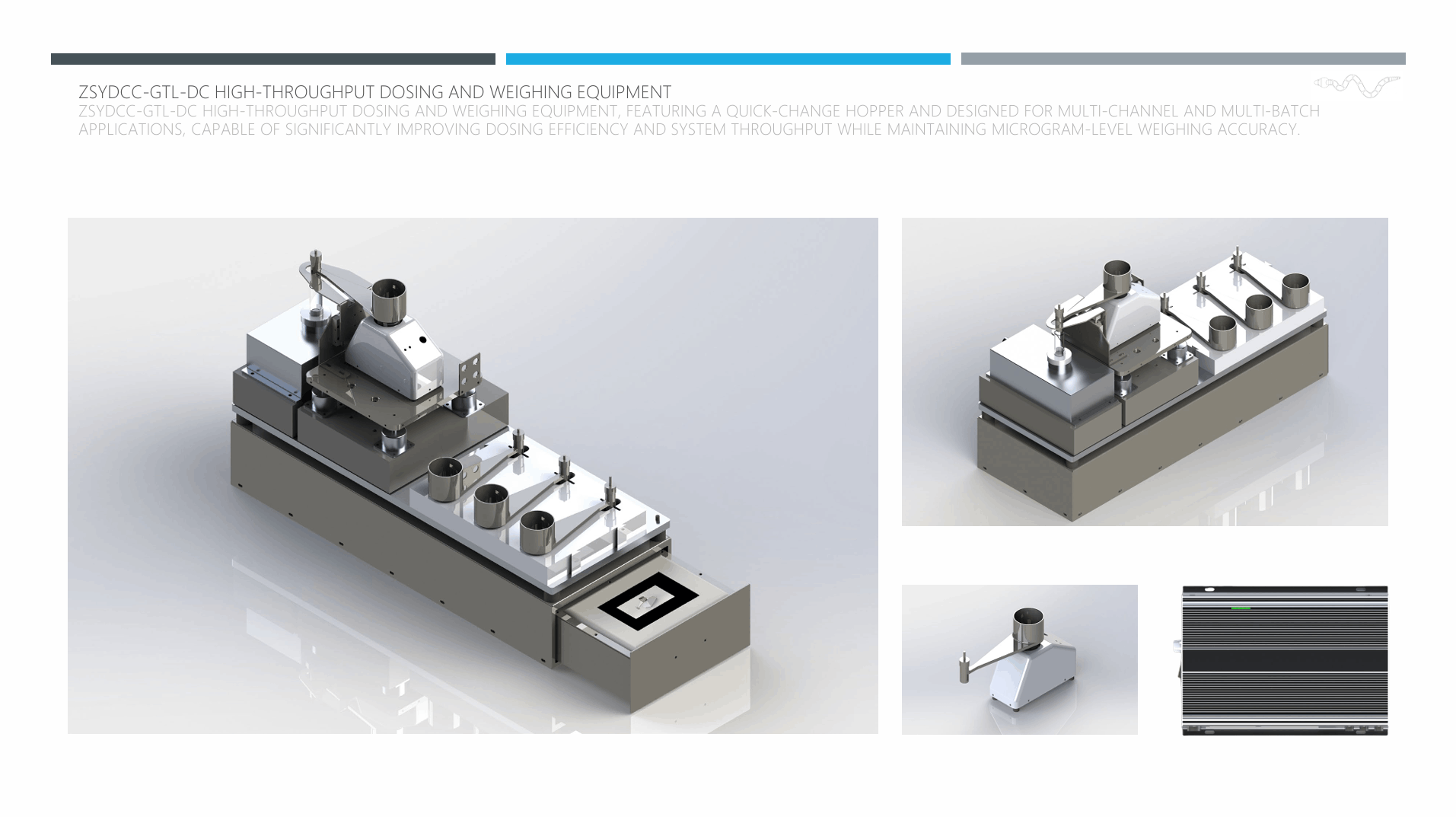

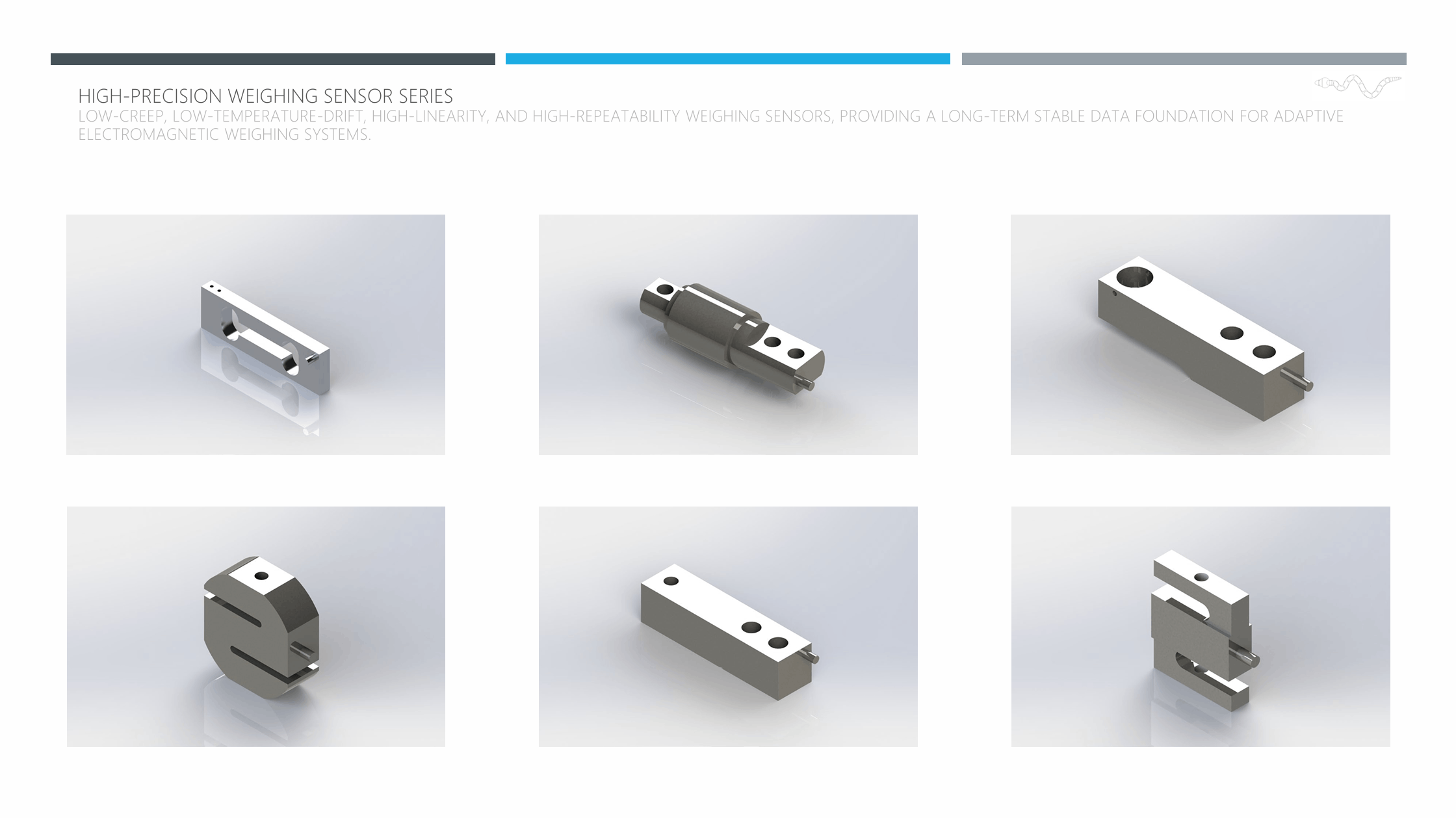

Leveraging high-performance constant-amplitude vibration hardware design in combination with adaptive micro-dosing algorithms, the system successfully overcomes the challenges of μg-level metering control, achieving stable, precise, and highly repeatable micro-scale dosing performance. It provides a reliable and professional solution for high-reliability applications and is widely used in laboratory high-throughput platforms, pharmaceutical R&D, and fine chemical analysis, where extremely high metering accuracy is required.

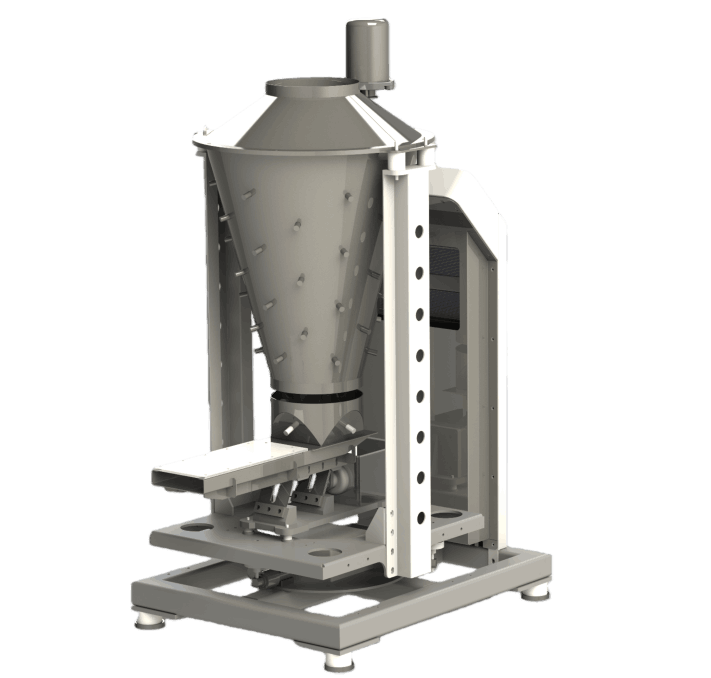

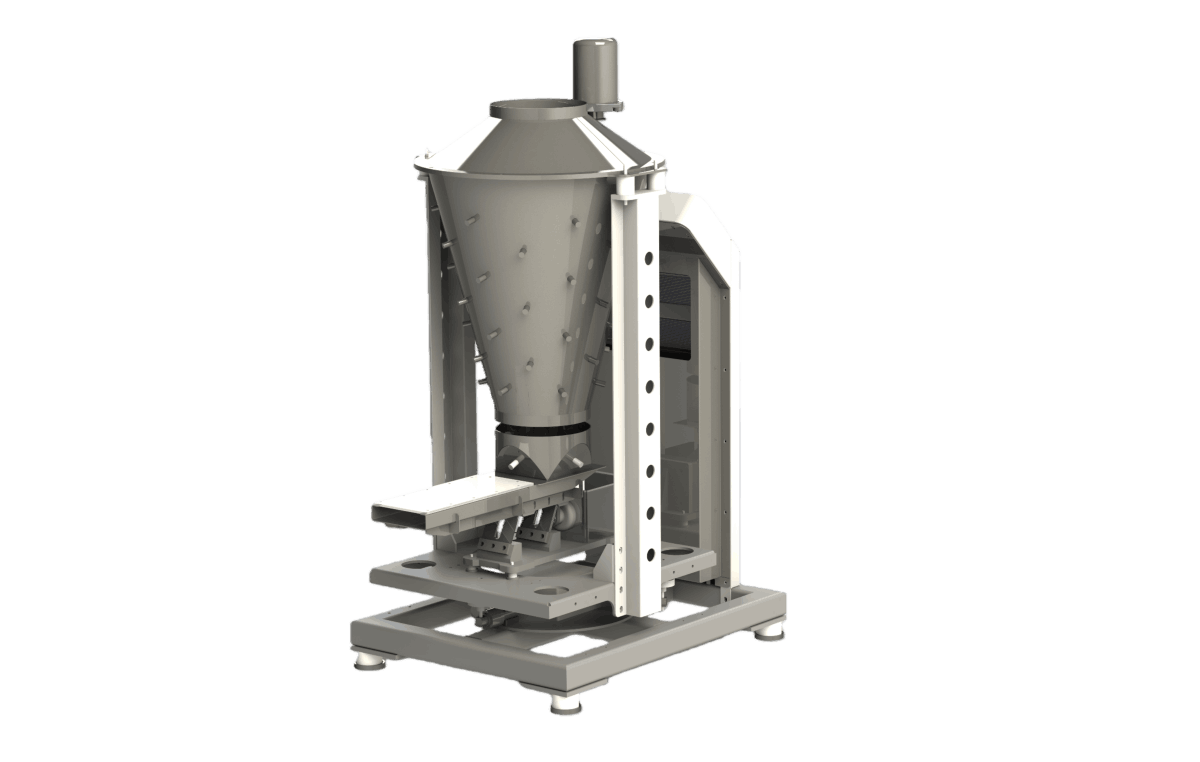

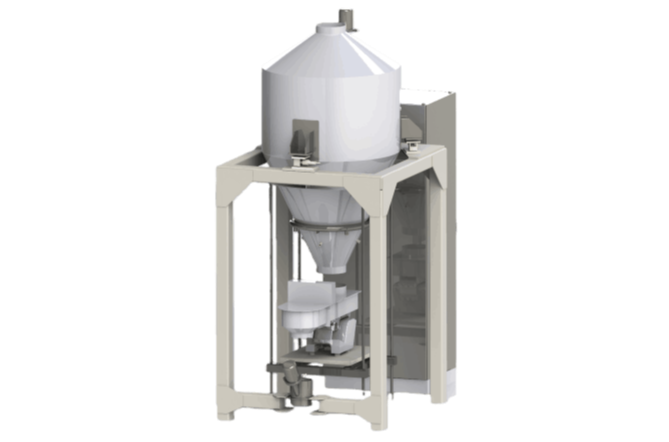

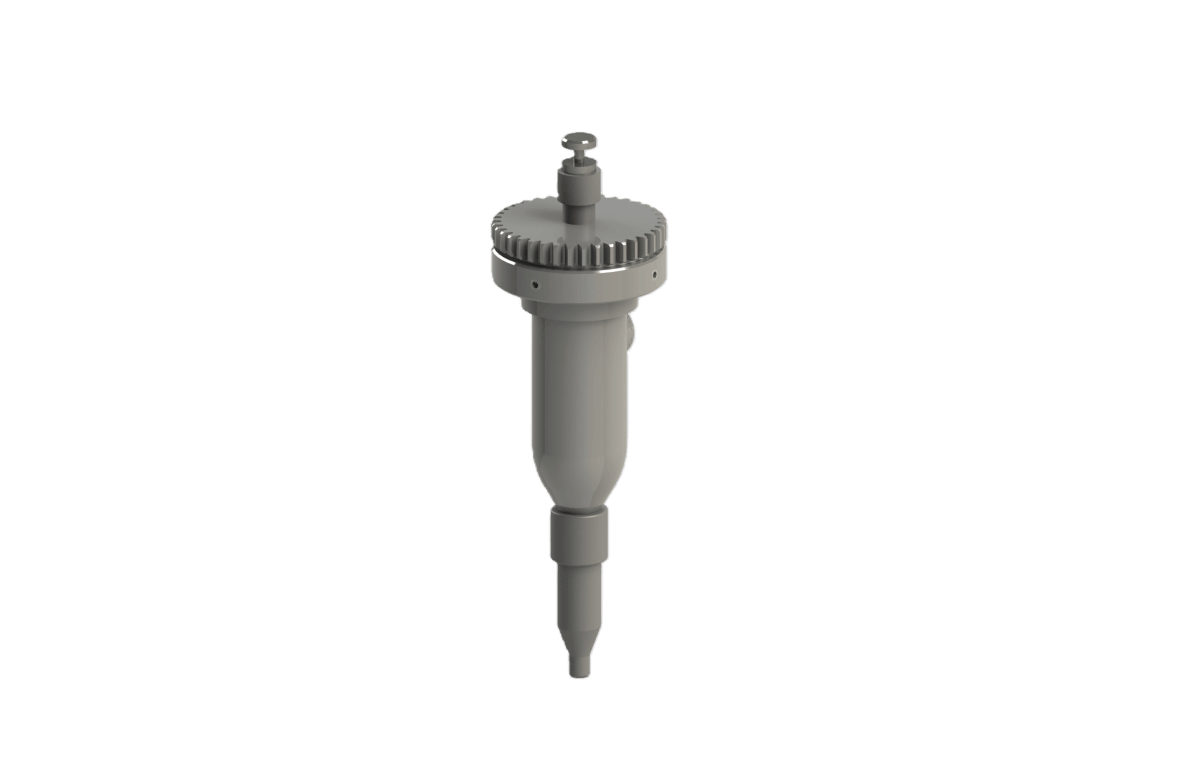

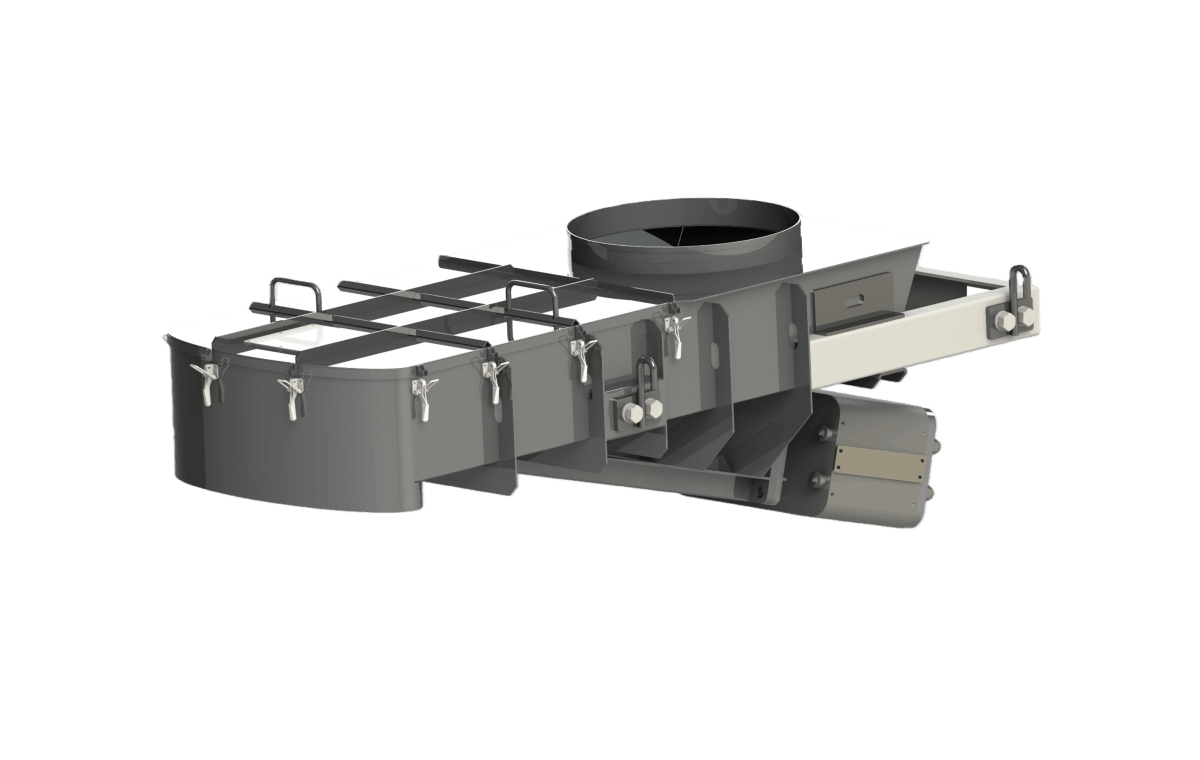

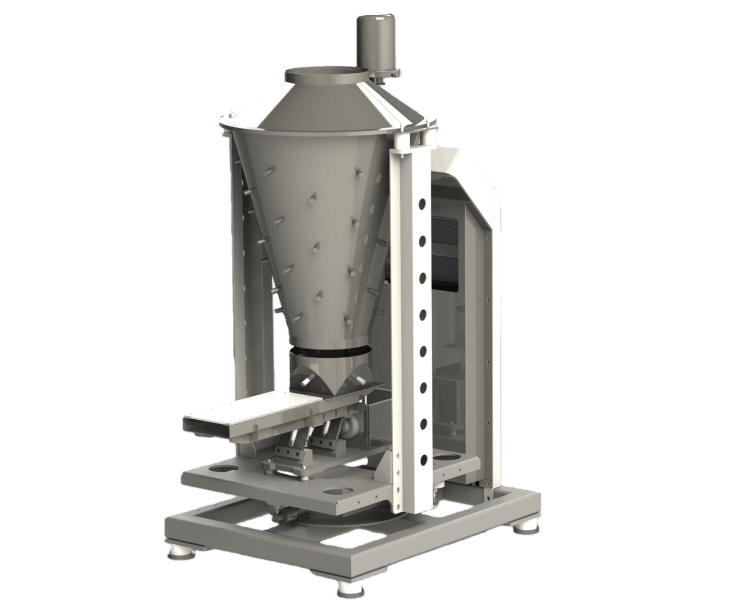

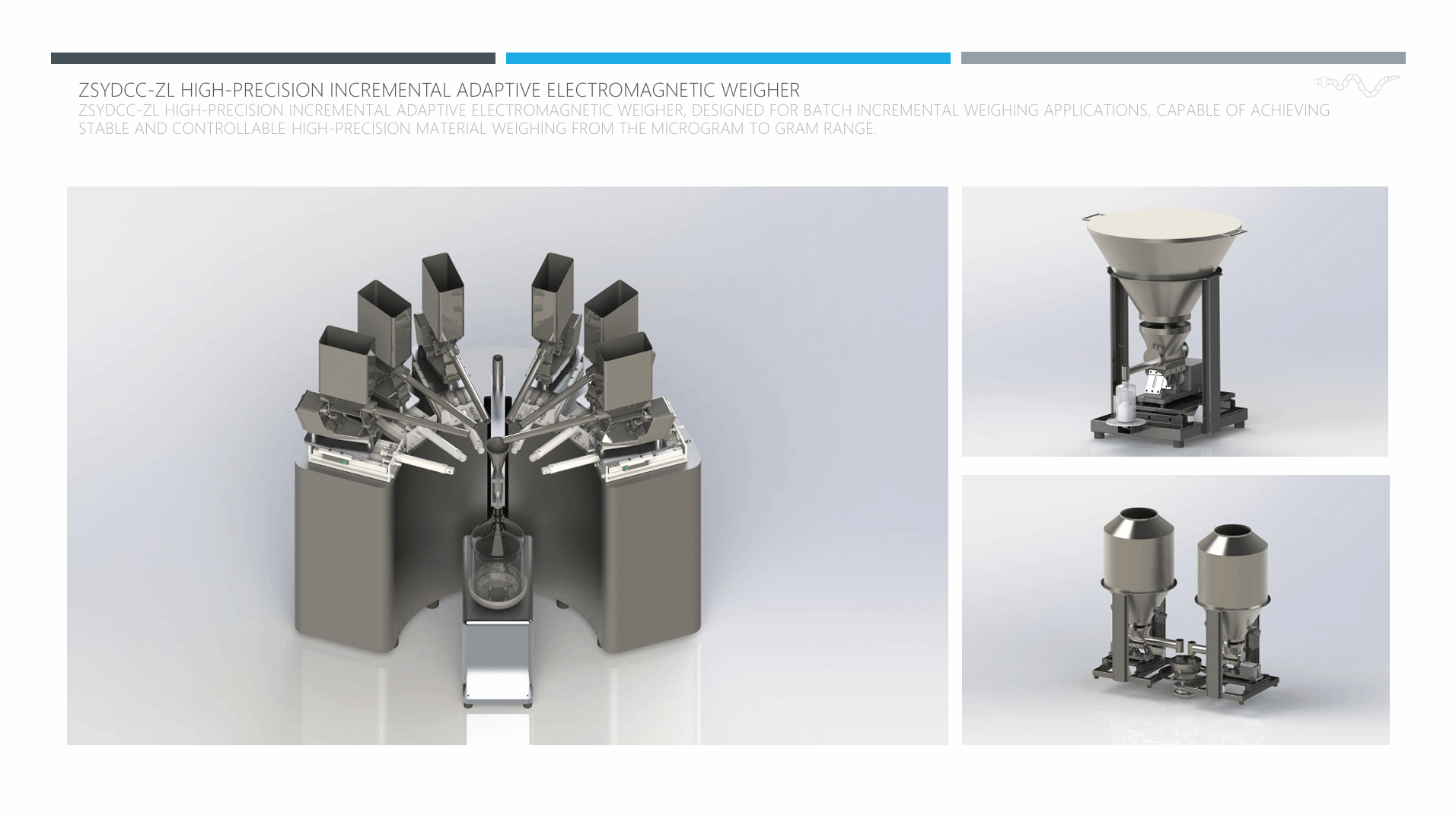

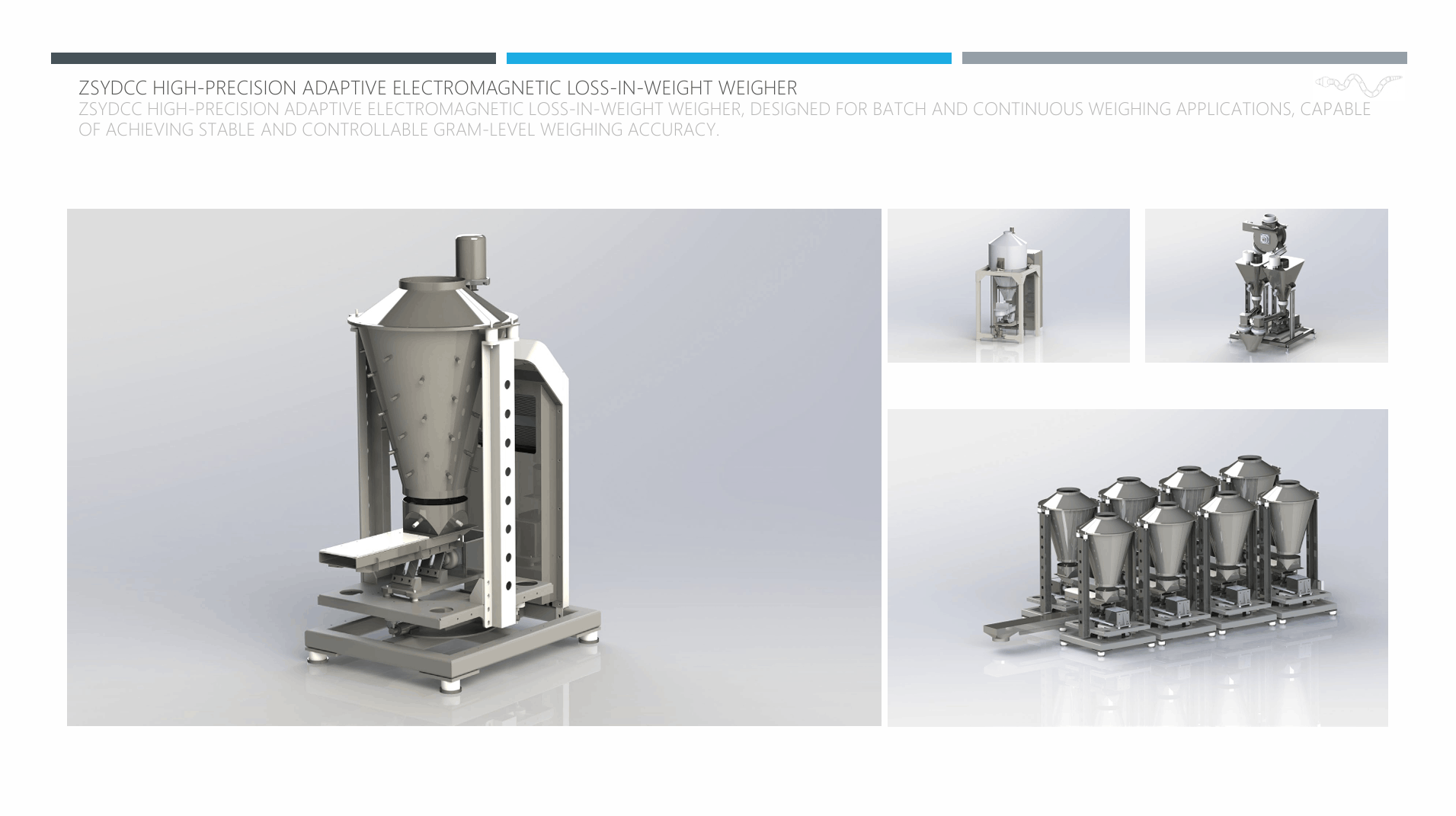

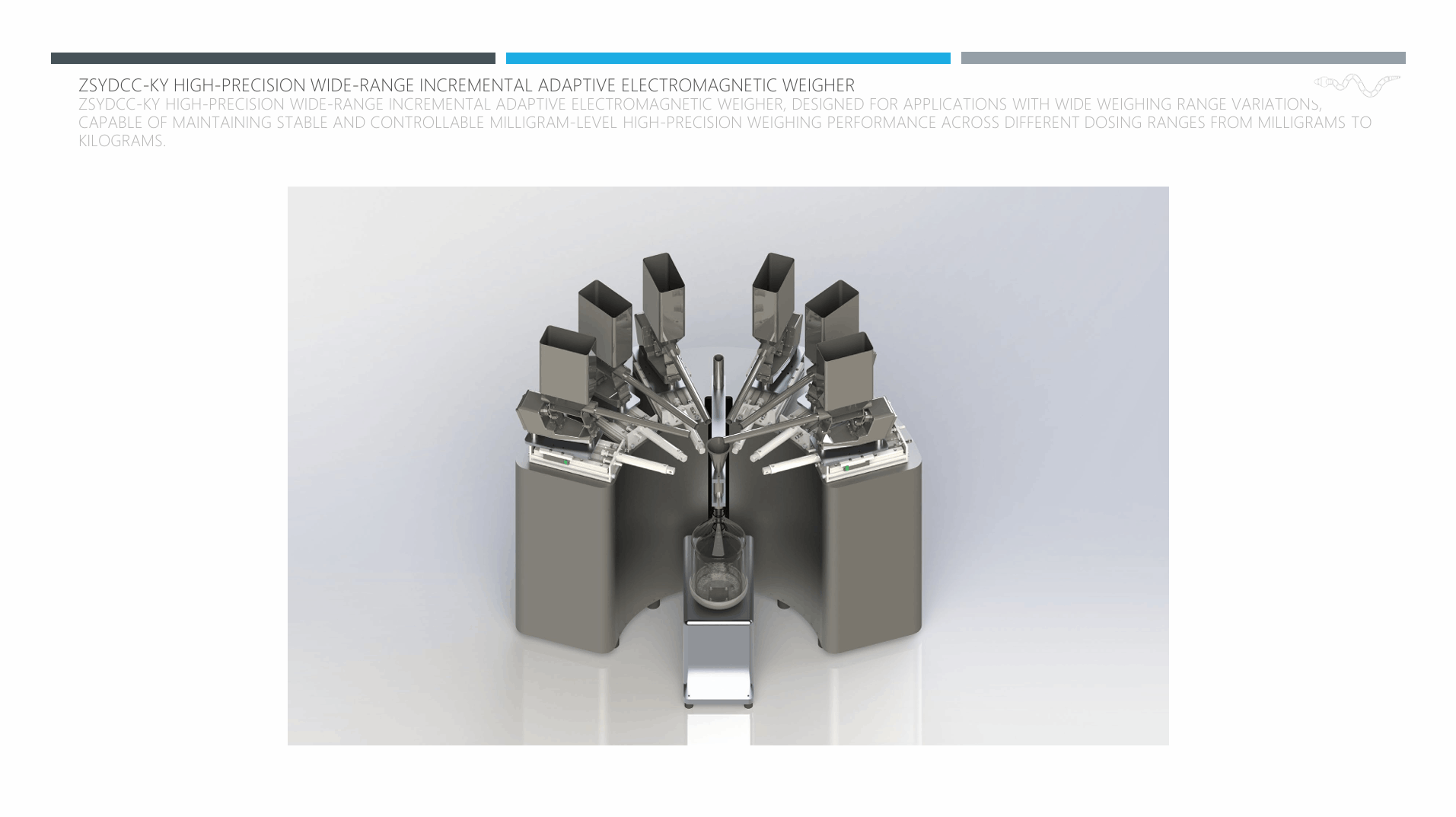

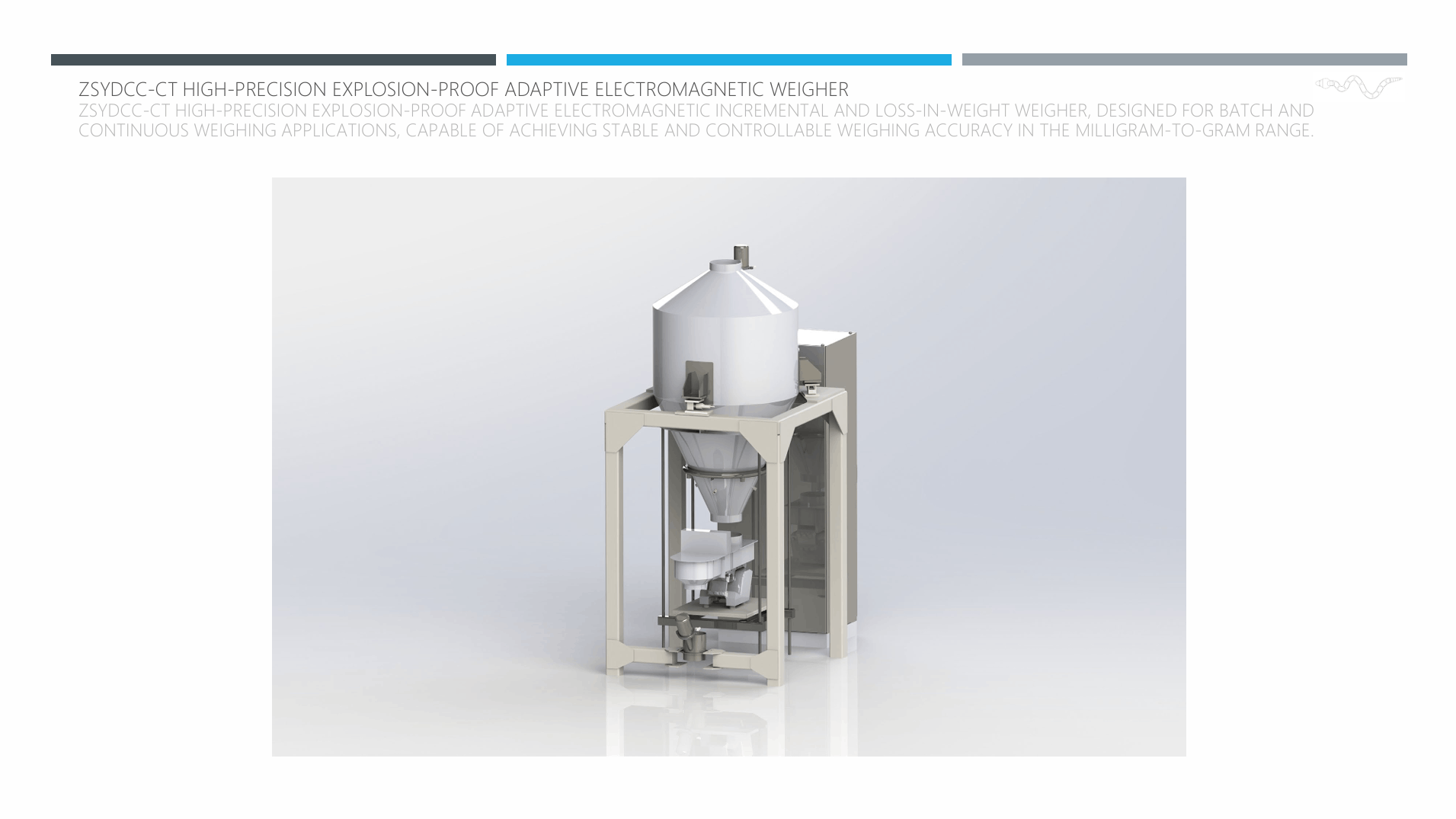

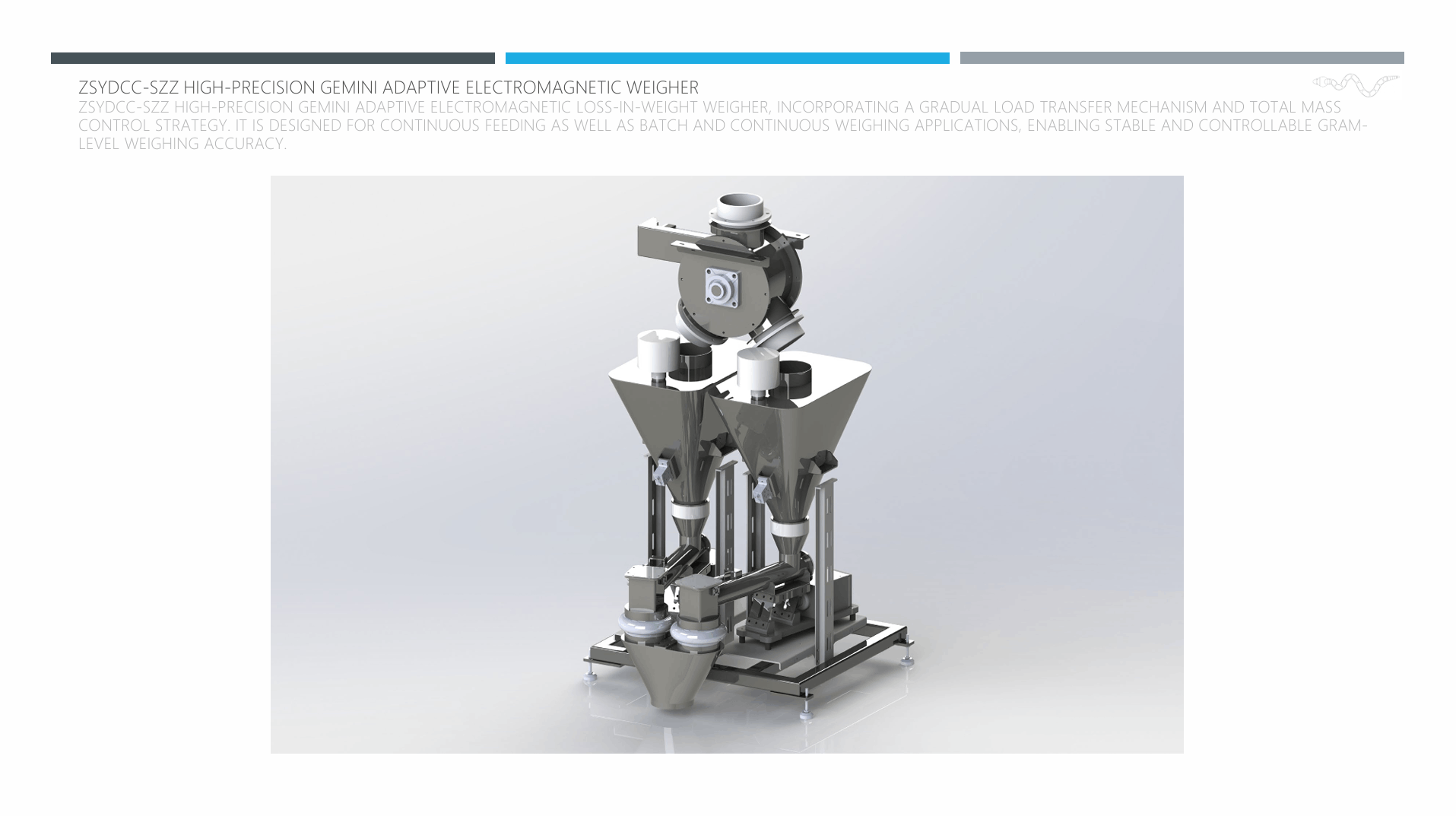

The adaptive electromagnetic scale features a unique constant-amplitude vibration structural design, combined with adaptive control and machine learning algorithms. This integrated approach effectively addresses the challenges of stability and accuracy when metering fragile and sensitive materials. While ensuring material integrity, the system delivers high-precision and highly repeatable metering performance, making it well suited for applications in laboratories, pharmaceutical manufacturing, and fine chemical industries where material integrity is critical.

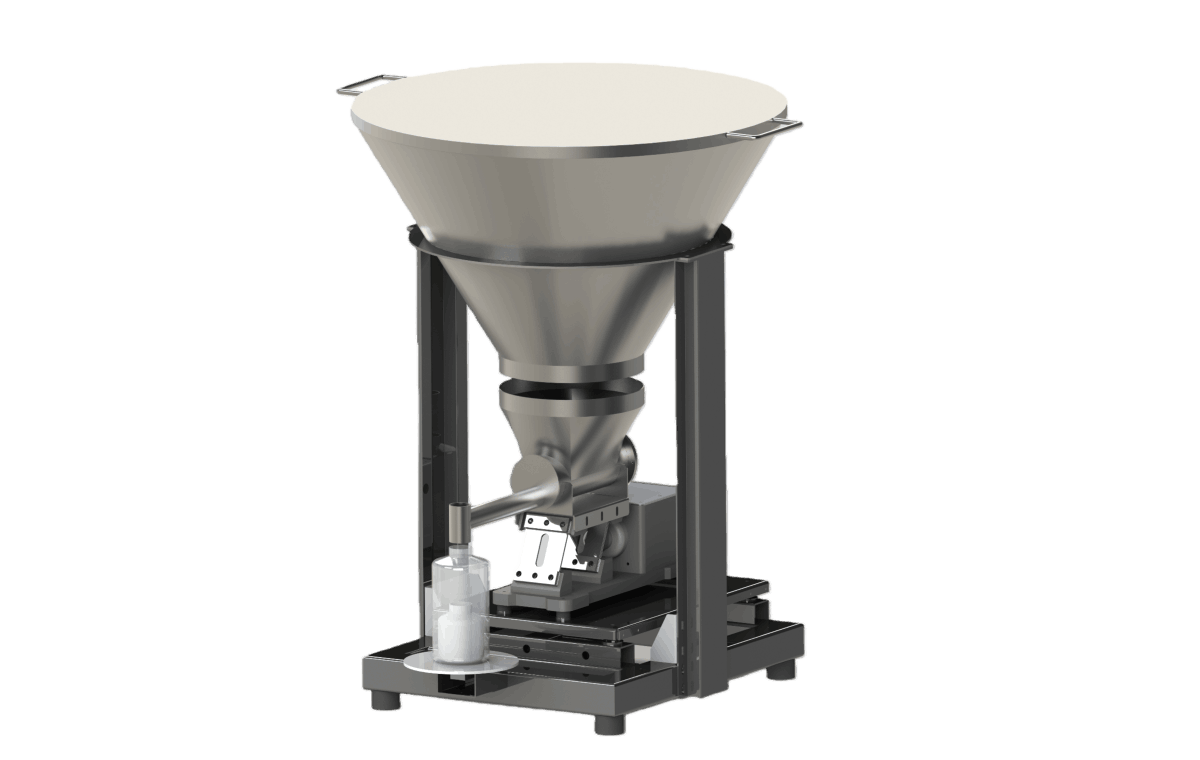

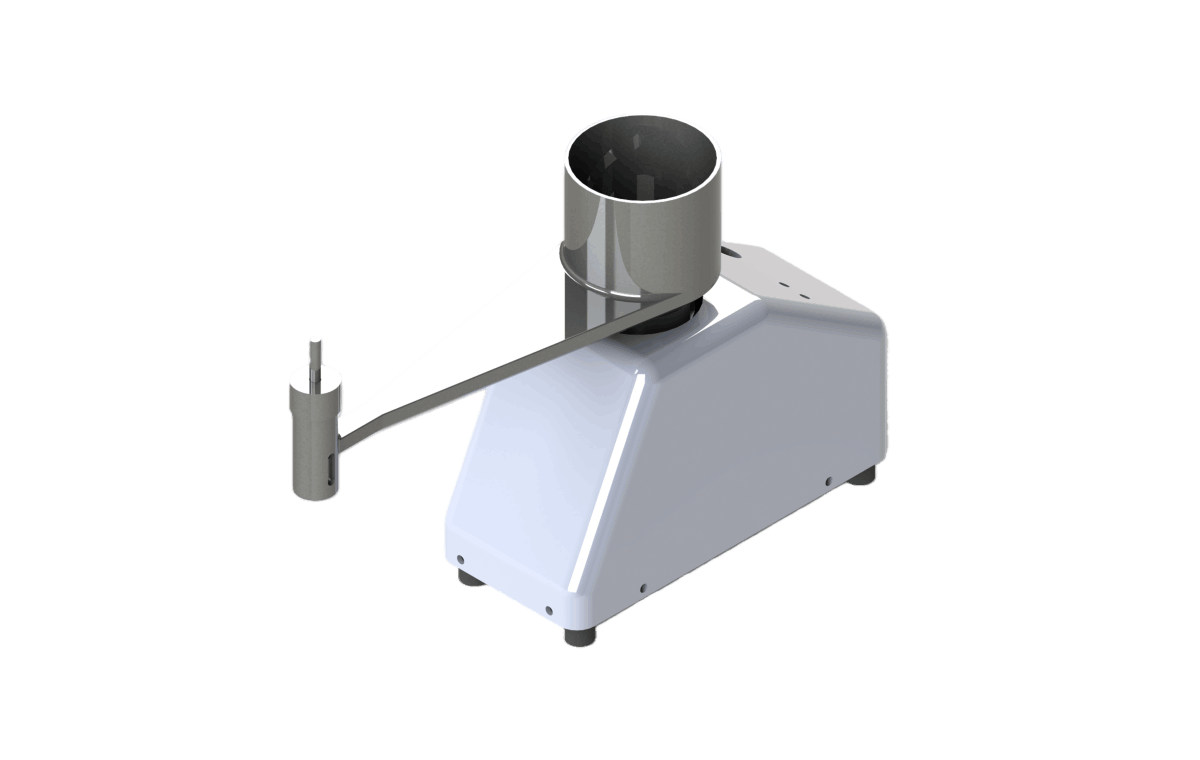

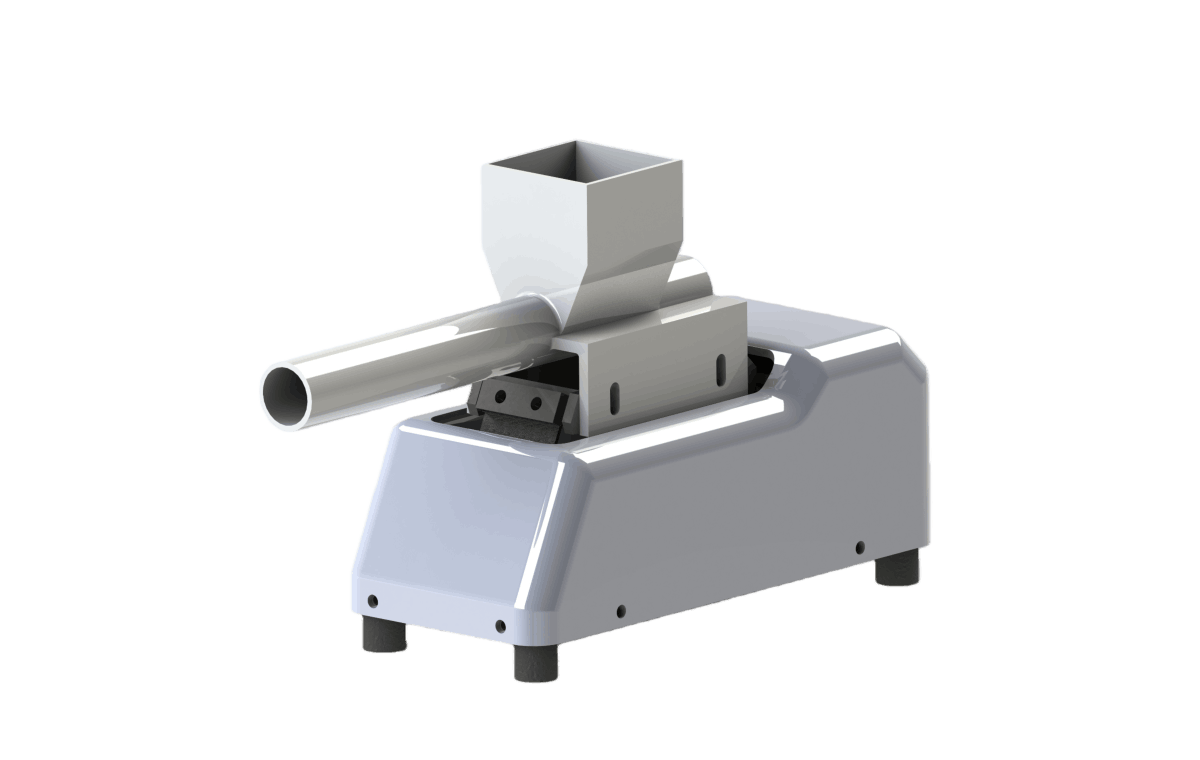

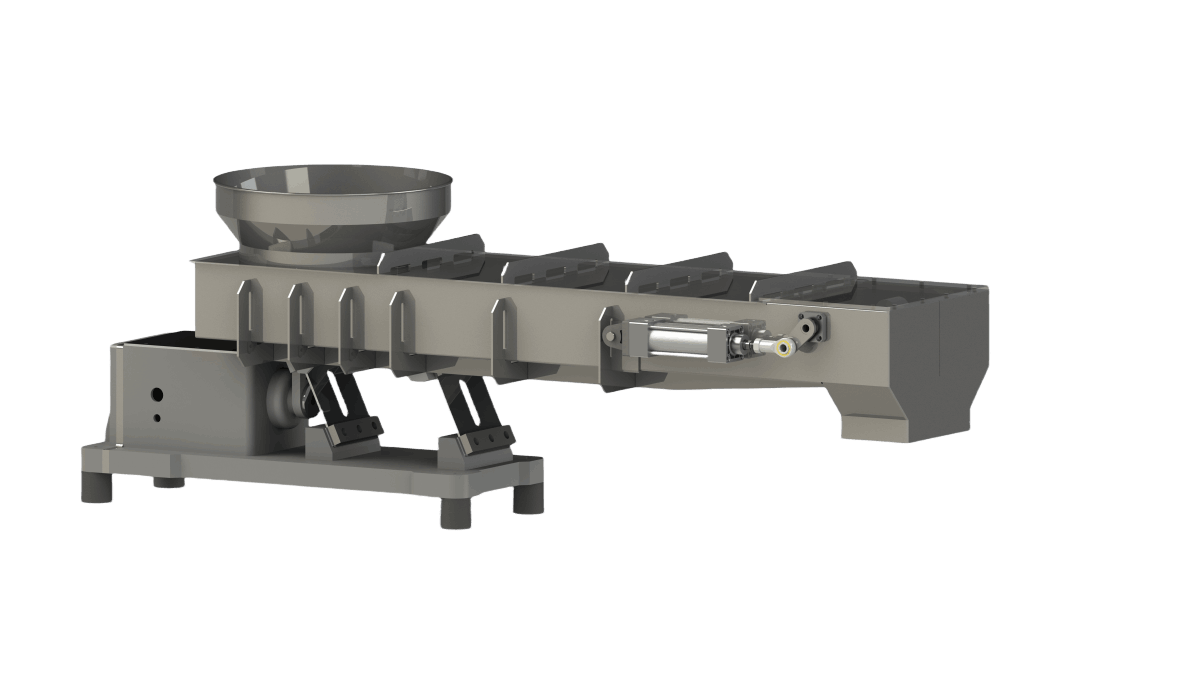

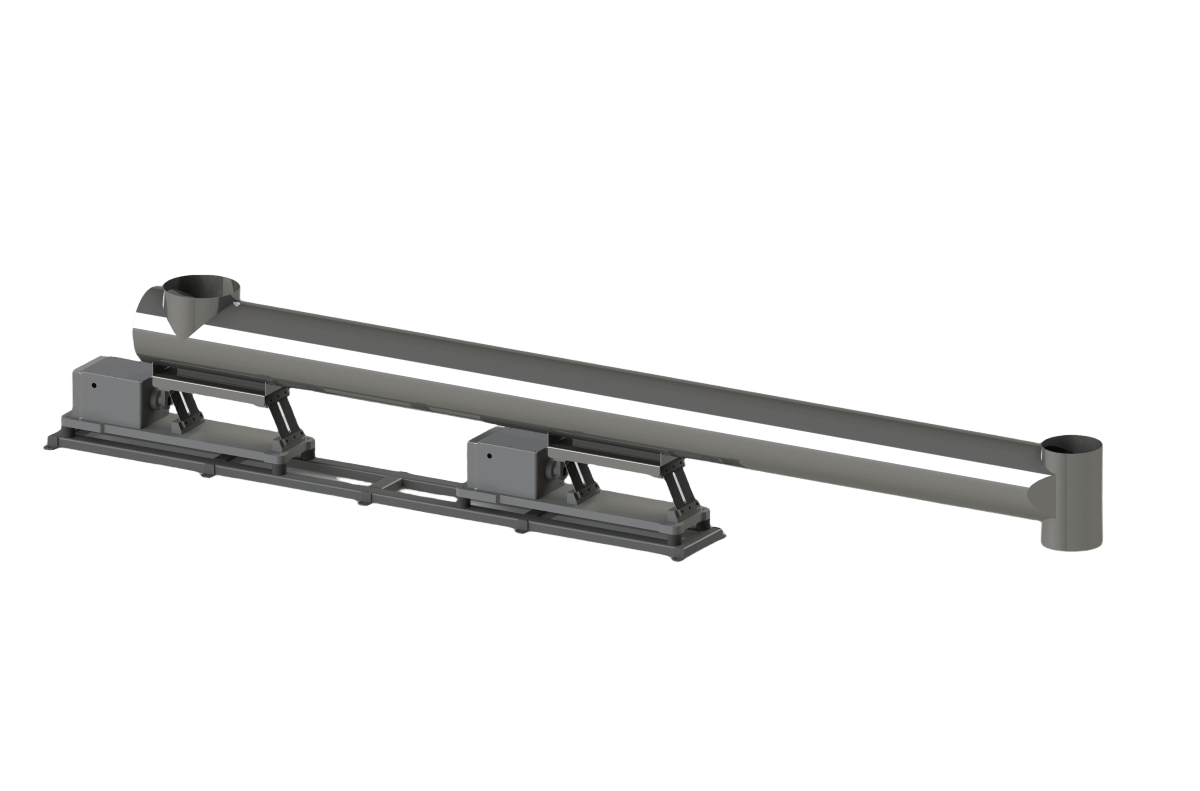

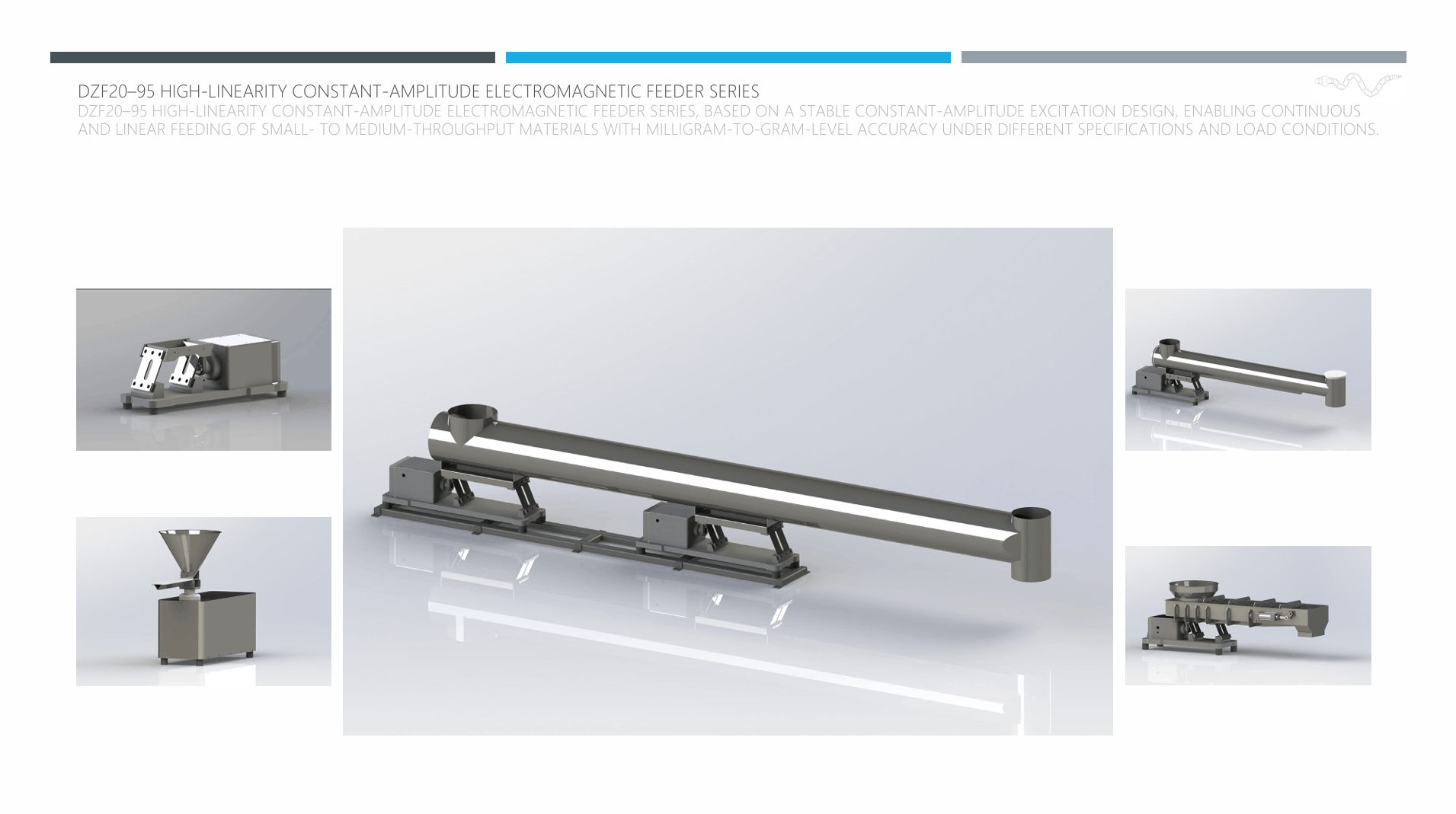

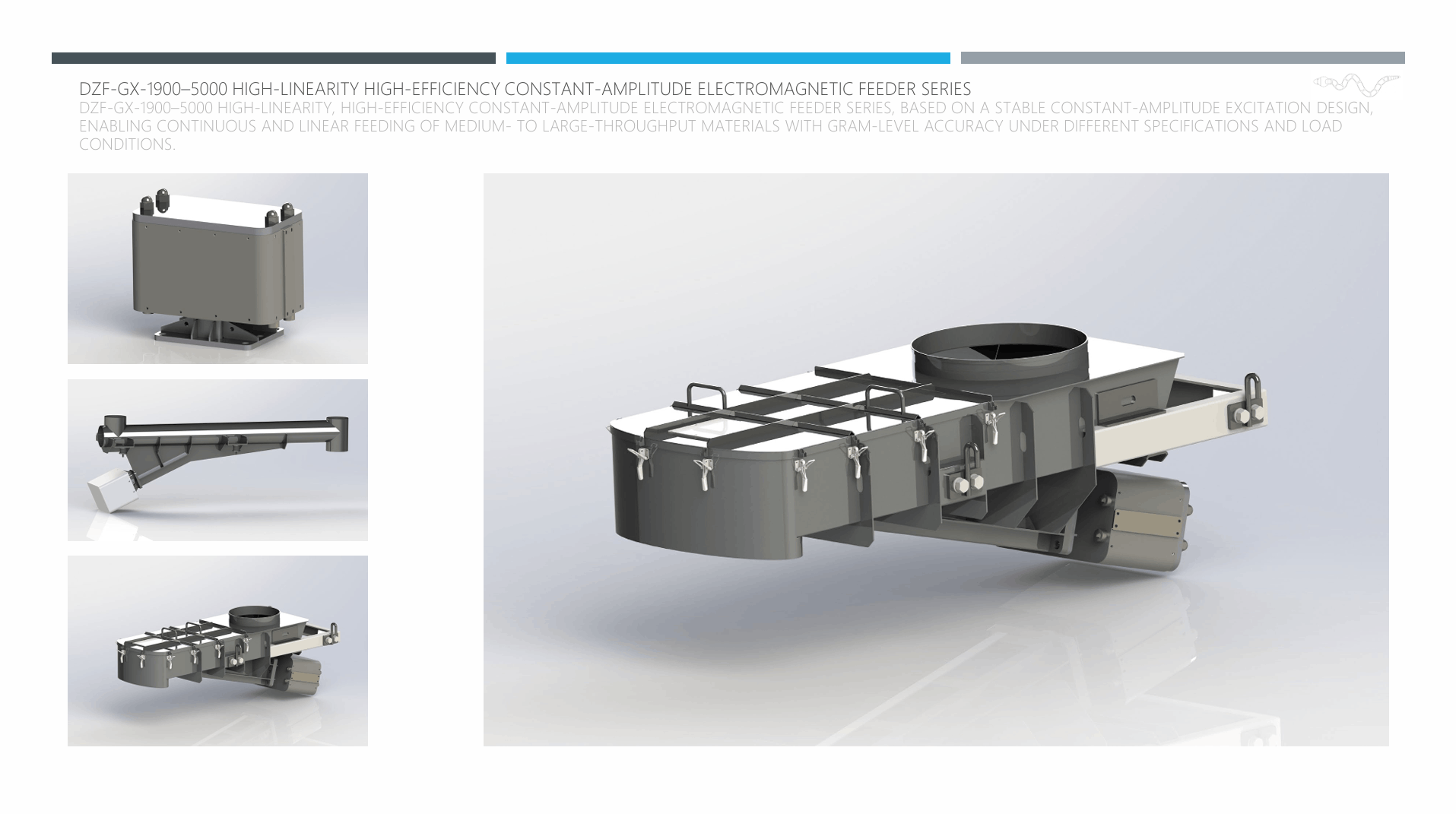

The constant-amplitude electromagnetic feeder adopts a low-stress, large-amplitude vibration structural design. While ensuring stable conveying performance, it effectively reduces material impact, significantly minimizing material breakage and segregation. It is particularly well suited for the continuous conveying of fragile and sensitive materials, substantially improving powder conveying efficiency and material quality consistency.